Our history

A legacy of engineering excellence

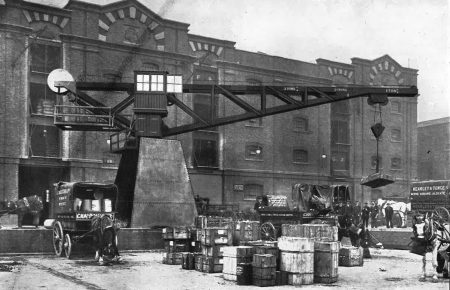

From the cranes that lined the Victorian docks to the high-performance passenger and goods lifts found in modern buildings today, Stannah has kept industry moving for over 150 years. Our commercial lineage is built on a foundation of heavy-duty engineering and vertical transport innovation. Scroll down the page to trace the evolution of our lifting expertise from 1867 to the present day.

Scroll down to explore our history

-

1867

It all began in Southwark, London, when Joseph Stannah, an accomplished engineer, started the Stannah business providing cranes and hoists to unload cargo in the docks.

1867

Back in the beginning...

The Stannah business was founded in London by Joseph Stannah in 1867. Joseph Stannah was the son of Solomon Stannah, a linen merchant in Worcester. An accomplished engineer, Joseph started the Stannah business in Southwark, London, providing cranes and hoists to unload cargo in the docks. He turned his hand to numerous problems and accumulated a raft of patents throughout his career. Among his designs for cranes and hoists are drawings for stuffing boxes, locomotives, pendulum pumps and there is even a tantalising reference to him having designed a car although we can find no firm confirmation of that.

However, we do know for certain that Joseph knew a thing or two about creating a public profile and was a regular contributor to the publication ‘The Engineer’, writing letters and publishing information about his patent devices.

Early 20th Century

Joseph’s son, Albert, took over the business around the turn of the 20th century, by which time the business had started to diversify into passenger and goods lifts – and even car lifts.

Early 20th Century

The second generation

While his father Joseph focused on industrial cranes and hoists for the docks, Albert took the business in a new direction around the turn of the 20th century. He expanded their product line to include passenger lifts, goods lifts, and car lifts, effectively turning them into a commercial lift manufacturer.

Historical records suggest he was instrumental in pushing the brand forward, placing advertisements in building catalogues to sell these new types of lifts.

He ran the company leading up to World War II. By the time the factory was bombed during the Blitz (which destroyed the business’s physical assets), Albert was in his late 70s. It was his son, Leslie (Pop), who eventually rebuilt the company from the rubble…

Post Second World War

Leslie Stannah, affectionately known as Pop, rebuilds the business after the factory is bombed during WWII.

Post Second World War

Rebuilding a business

Next in line was Leslie Stannah, also known as Pop, father to Brian and Alan, and grandfather to Jon, Patrick, Nick, Alastair and Helen. Born in 1901 to Albert Stannah and his wife Edith, he was a genuine character, known for his discipline on the one hand but real concern and kindness to his staff on the other. It was Pop who essentially rebuilt the Stannah business from scratch after the devastation of the Second World War.

As a young man Pop was an avid motorcycle enthusiast, retained by the iconic British motorcycle firm Ariel as a competitive rider and he won many events while riding for them. Pop didn’t join the family business on leaving education but went to work for other lift companies to gain experience. In fact, he still hadn’t joined the family firm by the outbreak of war in 1939 when he joined the Royal Navy.

After commendable service in the Royal Navy, Pop returned to London and to the ruins of the Stannah factory which had been hit by a bomb. By this time his father AJ was 77 and the business had ceased trading. With his demob suit, £300, and a bombsite where once a factory had stood, Leslie set out to rebuild the business. With incredible determination Pop started small and grew the business, manufacturing as many components of his lifts as possible. By the 1950s the business was on firm foundations and Brian and Alan were taking up apprenticeships in the industry ready for their ultimate entry into the business. Pop retired from the business in the 1960s and died at the age of 77 in 1979.

1960s

Brian Stannah leads a second regeneration, restructuring the business to focus on service contracts. In the same period, Alan Stannah pushed for streamlining production and standardising products, resulting in the launch of the Maxilift.

1960s

Brothers Brian and Alan Stannah bring critical innovation and diversification

The 1960s marked a pivotal era of regeneration for Stannah, driven by the fourth generation of the family, brothers Brian and Alan. While Brian restructured the business to focus on lucrative service contracts, Alan revolutionised the engineering side by pushing for standardisation. Recognising that bespoke manufacturing was inefficient, he championed a streamlined approach that reduced costs and lead times. This strategic shift culminated in the launch of the Maxilift, a standardised passenger lift that became a cornerstone of the company’s success and established Stannah as a serious player in the commercial lift market.

Beyond the core lift business, the decade was defined by a willingness to explore new opportunities despite a challenging economic landscape. This included a near-miss that turned into a triumph: the establishment of the Microlifts division. Although initially dismissive of a sales letter from Italian manufacturer Daldoss, the brothers reconsidered, retrieving the proposal from the bin to forge a partnership. This decision made Stannah the sole UK distributor for Daldoss service lifts—a relationship that not only diversified their portfolio but continues to drive sales to this day.

1970s

During a turbulent economic decade, Brian and Alan Stannah successfully launched the company’s first stairlift, moving production to Andover to meet growing demand. This era laid the groundwork for global expansion, establishing a nationwide service network and initiating their first international exports to Germany.

1970s

Innovation in the face of adversity

The 1970s were a transformative yet challenging decade, characterised by a biting recession, the three-day work week, and a fuel crisis. Despite these headwinds, Brian and Alan continued to diversify the business. Building on the success of the commercial Maxilift and the newly established Microlift division, the brothers sought a solution for homeowners struggling with stairs. After visiting a Dutch company, Jan Harmer, Brian purchased their designs, and the brothers began prototyping Stannah’s first stairlift. Manufacturing started in London in early 1975, and despite initial technical difficulties, they persevered to refine the engineering, selling 66 units in the first year alone.

As production processes improved, the operation quickly outgrew its London base, prompting a move to a purpose-built facility in Andover, Hampshire, where the business flourished. The stairlift was marketed not just as a mobility aid, but as an innovative alternative to moving house, endorsed by medical pioneers like Dr. Christian Barnard. To support this rapid growth in both the commercial and domestic sectors, Stannah established a dedicated service branch network starting in Manchester, Birmingham, and London. By 1979, the company had begun exporting to Germany, laying the foundation for a global presence that today spans over 40 countries.

1980s

To meet soaring demand, Stannah expanded manufacturing to Newcastle in the 1980s, leveraging the region’s engineering expertise to boost production capacity. This era also marked the introduction of platform lifts, significantly broadening the company’s portfolio of access solutions for public buildings.

1980s

National expansion and product diversification

With the stairlift business booming and the commercial sector steady, Stannah quickly outgrew its Andover capacity. In the 1980s, the company made a strategic move to set up a second manufacturing centre in Dunston, Newcastle. By acquiring R J Shaw and Company, Stannah tapped into the North East’s rich industrial heritage, finding that the local skill sets were invaluable for their growth plan. This new facility became a critical hub for rail manufacturing, ensuring the company could keep pace with its rapidly increasing sales volume.

This expansion in manufacturing capabilities paved the way for further product diversification. Utilising the new resources in the North East and the expanding Andover sites, Stannah introduced platform lifts to their range. This development was a crucial step in bridging the gap between their domestic products and heavy-duty commercial lifts, allowing the company to offer accessible mobility solutions for public buildings, schools, and retail spaces.

1990s

The 1990s marked Stannah’s transition into a truly international force, establishing subsidiaries across Europe and America while celebrating the production of their 100,000th stairlift.

1990s

A decade of global growth

By the mid-90s, the gamble on the domestic stairlift market had paid off in spectacular fashion, with the company celebrating the manufacture of its 100,000th unit in 1994. This exponential growth in production was matched by critical acclaim, as the company’s success in taking British engineering to the world was recognised with two separate Queen’s Awards for Export Achievement during the decade. These accolades cemented Stannah’s reputation not just as a UK manufacturer, but as a global leader in the mobility sector.

To support this booming international demand, the business moved beyond simple exporting to establishing a physical presence in key markets. The 1990s saw the launch of wholly-owned subsidiaries in the United States (1992) and Italy (1995), followed by further expansion into Europe. This strategic shift allowed Stannah to control the quality of service and installation worldwide, ensuring that the family ethos remained intact even as the business spanned multiple continents.

2000s

The new millennium saw Stannah surpass the 200,000 stairlift mark and welcome royalty to their factory, cementing their status as a British manufacturing icon.

2000s

Celebrating milestones and royal recognition

The 2000s began with a momentous occasion as Prince Charles visited the Andover factory to officially open the new assembly plant. This royal seal of approval underscored the company’s significance to British industry and the local community. The visit coincided with a period of rapid acceleration in production; having taken nearly 20 years to reach the first 100,000 sales, the company doubled that figure to hit the 200,000 mark early in the decade. This exponential growth was fuelled by continued product innovation and the strengthening of their international subsidiary network.

This era also marked a significant transition in leadership as the fifth generation of the Stannah family – Jon, Patrick, Nick, Alastair, and Helen – began to take active roles in the business. Under the watchful eye of Brian and Alan, this new generation helped steer the company through the digital age and further global expansion. Their involvement ensured that while the scale of operations increased, the core values of quality, service, and family ethos remained the driving force behind the brand’s success.

2010s to today

Stannah celebrated 150 years of engineering while significantly expanding its commercial lift portfolio and reaching the one millionth stairlift milestone. Under fifth-generation leadership, the company continues to modernise vertical transport for public infrastructure and private businesses alike.

2010s to today

Commercial innovation and historic milestones

The modern era has been defined by a dual focus on celebrating heritage and strengthening commercial capability. In 2017, the company marked its 150th anniversary, a testament to its evolution from Victorian hoists to a major force in the global lift industry. While the production of the one millionth stairlift in October 2024 was a historic headline, it was matched by significant investment in commercial infrastructure. The opening of the new manufacturing facility in Andover was a strategic move to boost engineering capacity across the board, supporting the production of the advanced passenger and platform lifts that are now essential to accessibility in public buildings.

Leadership now rests with the fifth generation – Jon, Patrick, Nick, Alastair, and Helen -who are actively driving the commercial division to meet rigorous modern accessibility standards. Beyond manufacturing, they oversee a comprehensive service network that maintains thousands of lifts across the UK, ensuring the reliability that business clients demand. Under their stewardship, Stannah has reinforced its position not just as a home mobility provider, but as a premier partner for architects and construction firms, delivering sophisticated vertical transport solutions alongside their domestic products.

Continuing the legacy: Our 2025 year in review